8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

Here is a vibratory feeder supplier talking about applications, uses, advantages and Featuresof vibratory feeders.

A vibratory feeder is a vibrating pallet. The vibration has a component that causes the particles on the tray to move with very little runout in the direction of the outlet end of the tray itself. Vibratory feeders have a variety of uses, the most common of which are similar to a conveyor belt, it transports the bulk product from the inlet end to the outlet end of the pallet. As a pure conveyor, the vibrator is at a disadvantage compared to a belt because the conveying speed is slower, its length is limited due to its construction, and although it can be conveyed by product vibration, it loses its higher conveying speed.

It is a conveyor that has another machine feeding at its end or outlet.

The vast majority of machines that perform sorting (screens, Foucault separators, magnetic, optical, etc.) require feeding over the entire functional width of the sorting machine itself. Without this type of feeding, these machines would significantly degrade their performance.

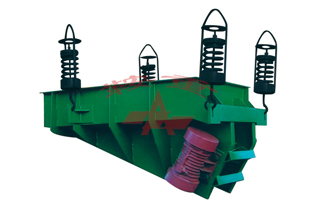

Vibratory Feeder

Vibratory feeders allow for the extension of the bulk product to occupy the entire width of the tray so that when it is poured onto the sorter, the width of the bulk product spreads out.

The specific geometry of the vibratory trays is also used to better achieve this distribution effect.

When installed at the bottom of a hopper or bin or in a tunnel under a product stock, it has the ability to extract product at the desired rate in a constant and uniform manner.

This is important at the beginning of any production line as it allows the product to be introduced at a properly regulated and uniform flow rate during the process so that subsequent machines can operate properly.

It has the function of extracting the product at the desired rate in a constant and uniform manner, when installed at the bottom of a hopper or silo, or inside a tunnel under a product stock.

This is very important at the beginning of any production line since it allows to introduce the product in the process with a uniform flow properly regulated, so that the successive machinery can function properly.

A vibratory conveyor also has its advantages because it is less likely to be torn or burned into a metal pallet in the form of a belt, and there is no product spillage in the typical belt return section.

GZZ Series Vibrating Grizzly Feeders are developed to handle ROM material , used in feeding primary crusher, reducing load on primary crusher and withstand constant abuse because of blind plate in feed end, grizzly bars in discharge end. Fines removed prior to crushing saves valuable energy and can sometimes result in smaller primary crushing capacity requirements.

Vibrating Grizzly Feeder

● Double eccentric shaft ,adjustable timing gears in exciter.

● Varying the speed by using a frequency controller.

● Extra-heavy construction, deep side channels, extra-heavy cross members and heavy coil spring support system.

● Fixed or adjustable stepped grizzly openings

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap