8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

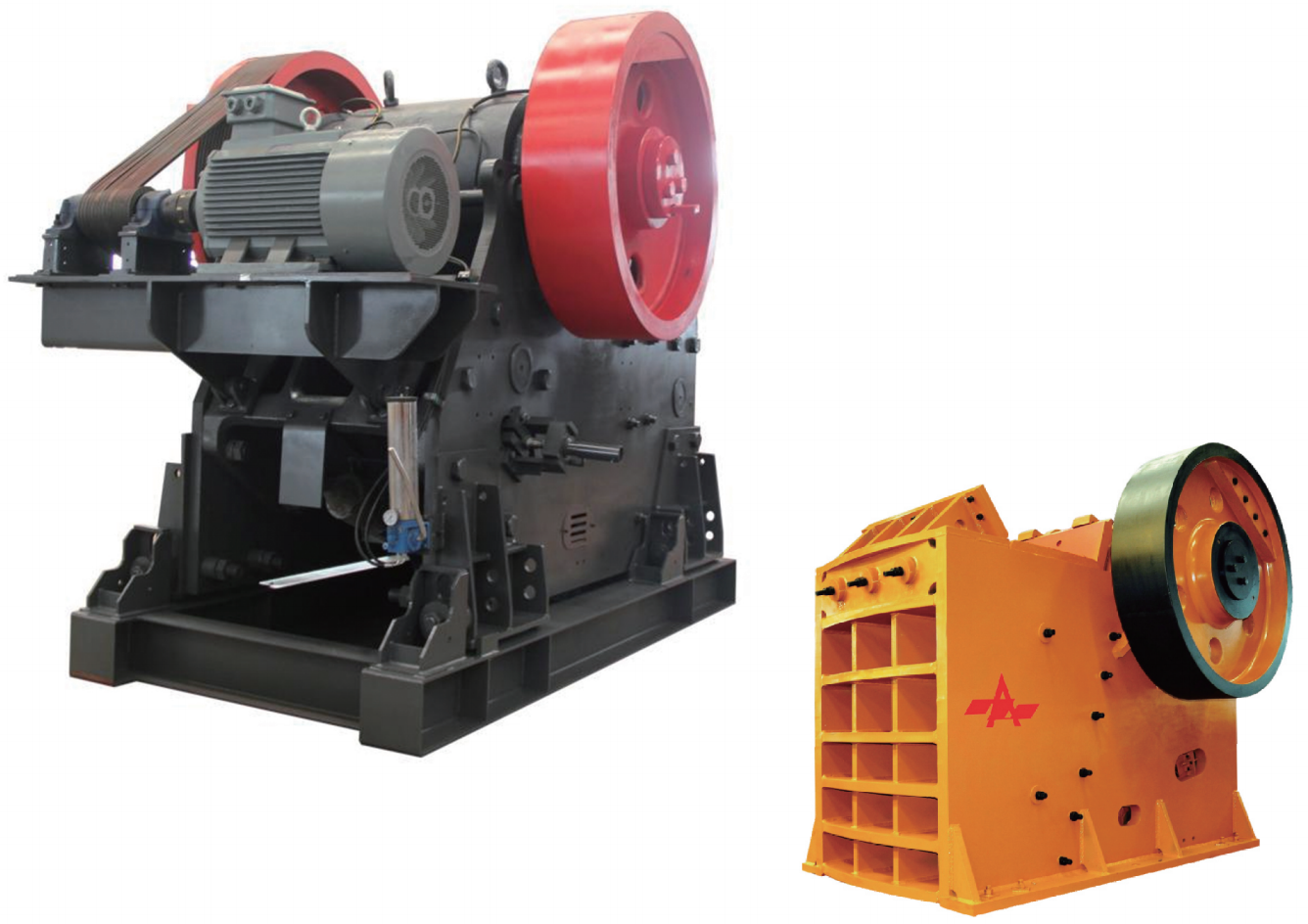

Jaw crusher is suitable for crushing various types of ores, shale, coal and other materials. Widely used in mining, metallurgy, chemical industry, building materials, electric power, water conservancy, transportation and other fields. It can meet the most demanding coarse crushing operation requirements economically, conveniently and safely.

product details

Industry solutions:lHigh capacity, large crushing ratio, low wear and large feed size.

The deep-cavity symmetrical crushing chamber design of the jaw crusher maximizes the feed size, capacity and crushing ratio of the crusher. The design of the motion mechanism combined with the crusher's operating speed enables the crusher to achieve greater output and lower jaw plate wear. The ideal crushing angle ensures the materials are crushed and passed smoothly, making the crushing ratio larger.

lReliable heavy-duty movable jaw assembly

The movable jaw is made of high-quality cast steel and is driven by a large cast pulley and flywheel. The forged heavy-duty eccentric shaft and high-quality large-scale spherical roller bearings made of SKF or FAG make the crusher extremely reliable. The head of the movable jaw is equipped with a replaceable guard plate to effectively protect the movable jaw from the impact of the feed.

lSolid body structure

The body frame is composed of a cast steel fixed jaw at the front end, rolled steel plates on both sides and a cast steel adjusting seat at the rear. All butt welds are used to improve the stress of the steel plates. After the frame is assembled and welded, it is overall annealed to make the frame high strength, durable and simple in structure.

lWedge outlet adjustment system

The mechanical or hydraulic wedge outlet adjustment system is simpler and safer than the gasket adjustment system.

lSymmetrical crushing cavity

Symmetrical crushing cavity design improves crushing efficiency.

lInstallation method without anchor bolts

The good balance performance allows the crusher to be installed without anchor bolts. The normal operation of the crusher can be achieved through the rubber damping blocks installed on the bottom and sides of the crusher support, which can slow down vibration impacts and avoid damage to the foundation.

lIntegrated motor installation

The motor support is integrated with the crusher, which reduces the installation space of the crusher and the length of the V-belt, making it simple to use and extending the service life of the V-belt. It can also be equipped with standard pulley covers and flywheel covers.

lCentralized lubrication system for easy maintenance.

The eccentric shaft can be lubricated manually or equipped with an automatic lubrication device (optional)

lEasy installation for convenient transportation

The crusher can be easily transported in different ways according to different transportation requirements (such as underground installation or weight and space restrictions)

The flywheel/moving jaw can be transported separately, as a whole, or even as the frame is disassembled.

Technical Parameters

Model | PEC80 | PEC100 | PEC125 | PEC140 | PEC160 |

Maximum feed size(mm) | 400 | 630 | 750 | 850 | 1000 |

Inlet size(mm) | 510X800 | 760X1000 | 950X1250 | 1060X1400 | 1200X1600 |

Outlet range(mm) | 40~175 | 70~200 | 100~250 | 125~250 | 150~300 |

Motor model | Y280S-4 | Y315S-4 | Y315L1-4 | Y315L2-4 | Y355M2-4 |

Motor power(Kw) | 75 | 110 | 160 | 200 | 250 |

Production capacity(t/h) | 65~380 | 150~450 | 260~780 | 300~800 | 500~1100 |

Spindle speed(r/min) | 350 | 260 | 225 | 220 | 220 |

Dimensions(mm) | 2725X2066X2259 | 3867X2352X2955 | 4391X2849x3997 | 4912X3178x4237 | 5710X3499x5122 |

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap